Technology

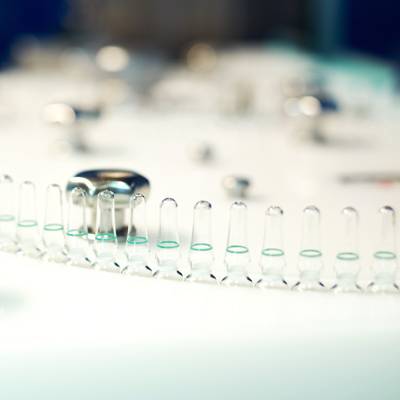

We are working to develop high technology products for the administration of innovative drugs.

in the world

several countries

authorizations

share

Continuous research and development of new and innovative technologies.

We collaborate with some of the most important international pharmaceutical companies to develop products that require greater capacity and flexibility.